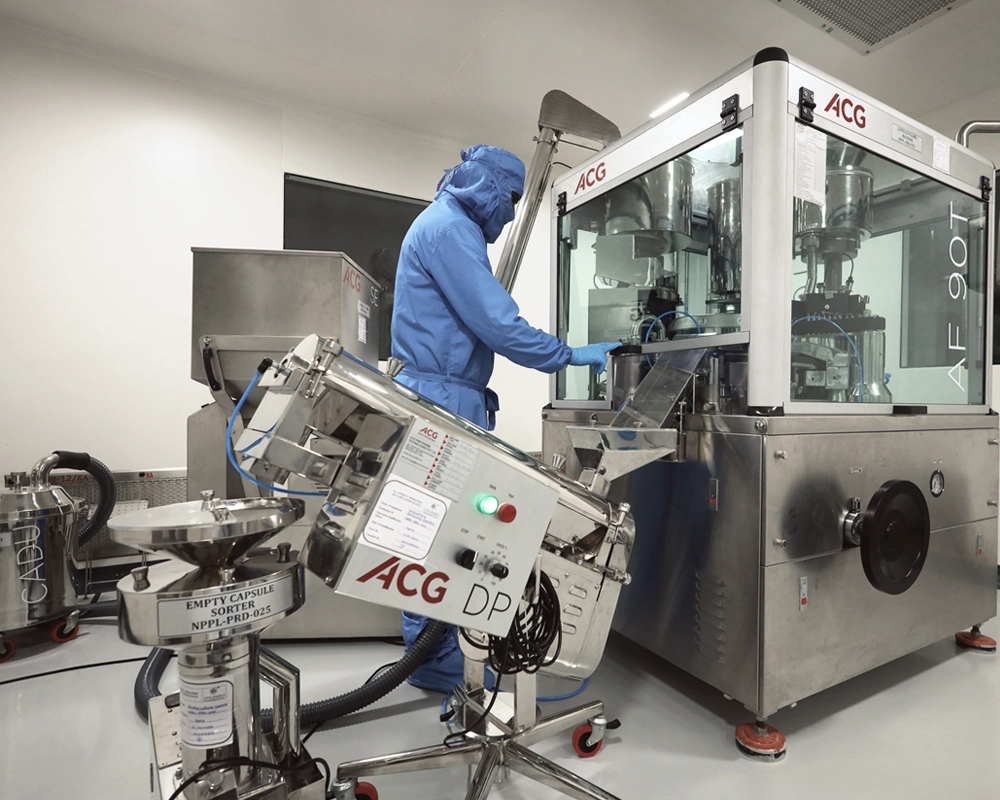

Manufacturing Capability

Nourish Pharmaceutical is equipped with state-of-the-art manufacturing technologies꞉

These facilities underline our commitment to delivering high-quality pharmaceutical products efficiently, aligning with global manufacturing standards.

Nourish Pharmaceutical Pvt. Ltd. has advanced manufacturing facilities with salient features designed for peak efficiency, safety, and adherence to global standards.

These salient features are -

Streamlined Workflow Design

Our facility is strategically laid out to ensure a unidirectional flow of personnel and materials, Zero cross-contamination and optimizing efficiency. Each area is specifically designed for handling different stages of production within a controlled climate environment.

Spacious Warehouse and Material Handling

Equipped with designated quarantine and storage areas for raw materials, our facilities facilitate precise and secure management of Active Pharmaceutical Ingredients (APIs) and excipients.

Advanced Quality Control Laboratory

Featuring state-of-the-art instruments like H.P.L.C., F.T.I.R., K.F.A. and UV spectrophotometry, our QC lab conducts rigorous quality assessments. It includes specialized micro labs and stability chambers to meet stringent quality standards.

HVAC System with Enhanced Air Quality

Classified under Class D, our core process areas feature individual AHUs with HEPA filters to maintain optimal air quality, temperature, and humidity through an automated system.

Advanced Cleanroom Technology

Our cleanroom setup with partitions and flush doors ensures a contaminant-free environment critical for maintaining the integrity of our products.

Highly Sophisticated Purified Water System

A two-pass Reverse Osmosis (RO) system with online sensors and Electrodeionization (EDI) guarantees the highest levels of water purity necessary for pharmaceutical manufacturing.